Chiller System Pdf

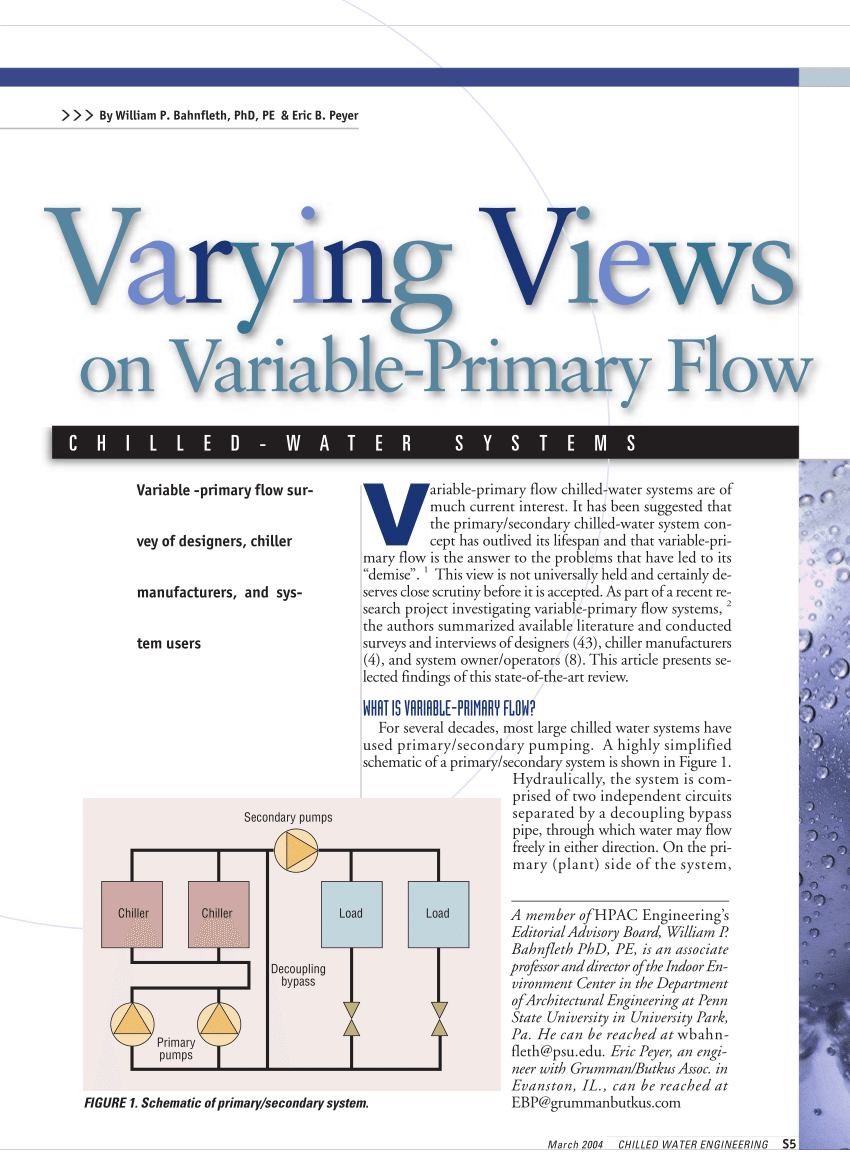

Chiller system pdf. Usually the main reason for a high approach is due to fouling of condenser. The chillers piped in parallel have a flow rate greater than those in a traditional primarysecondary system because the sidestream pump does not help satisfy system chilled water flow requirements. System flow below chiller min flow 250 gpm Variable Primary Flow at 25 System Load Two-way valves control capacity By varying flow of water in coils Per Chiller System Load 50 Tons 176kW 50Tons 176 kW Primary Bypass Flow 250 gpm 95 ls 150 gpm 95 ls Delta T 12 oF 67 oC ----100 GPM 44 ºF 63 ls 67 ºC 56 ºF 133 ºC 150.

The premise of a primary-. Chilled Water Systems - Back to Basics Jonathan Ramajoo Peter Wise 17 October 2012 AE Smith was established in Melbourne in 1898 by Alfred Smith Senior and the company remains a family business today. 22 Refrigeration System Efficiency The cooling effect of refrigeration systems is generally quantified in tons of refrigeration.

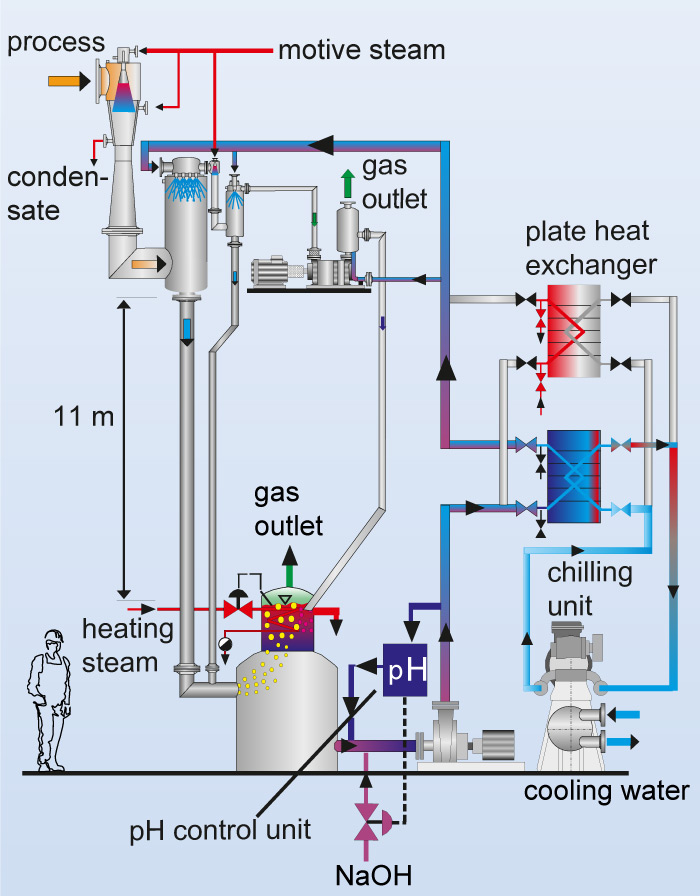

Specific application considerations for absorption chillers are addressed in another Trane publication Absorption Chiller System Design SYS. Bypass line sizing in variable flow systems dynamically varying condenser water flow number of chilled-water pumps to operate series chillers and power consumption whether to use pressure-independent control valves Primary-secondary system bypass sizing. It is designed to release the chemical energy stored in the fuel converting it into mechanical work that can then be put to a useful purpose.

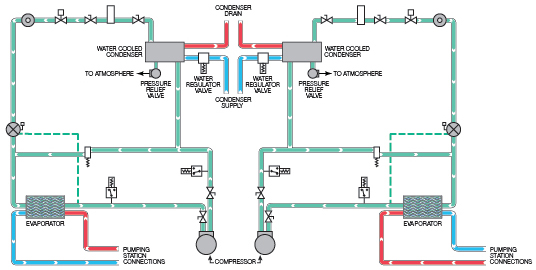

AE Smith The company employs around. A chiller piped in a sidestream position shown in Figure 8 can be loaded to any load condition by varying its chilled-water setpoint. The chiller system is controlled so the system will not operate unless the circulation pump is running.

Chilled-water system designs include. Parameters Affecting Engine Transfer Engine heat transfer depends upon many parametersunless the effect of these parameters is known the design of a proper cooling system will be difficult. Industrial chillers are an integral part of keeping large commercial buildings comfortable during the warmer months.

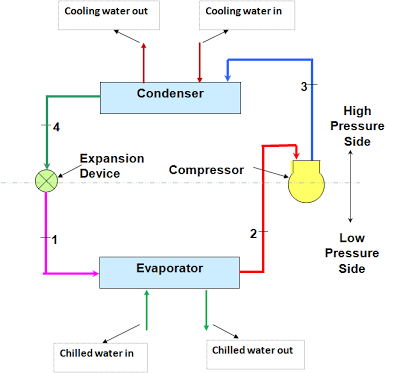

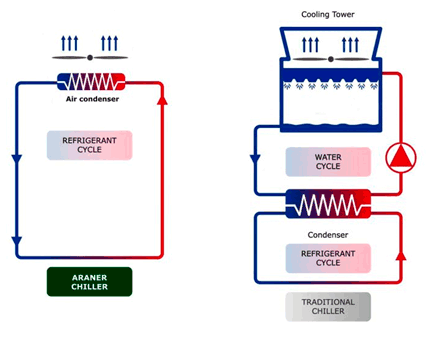

When selecting a chiller the application cooling temperature requirements and refrigerants cooling characteristics need to match. A vapor-compression chiller uses a refrigerant internally as its working fluid. A chiller is a machine that removes heat from a liquid via a vapor-compression or absorption refrigeration cycle.

They typically work in conjunction with a cooling tower which helps reduce the overall temperature of the cooling system. Many refrigerant options are available.

The process pump takes the chilled glycol from the tank to the process cooling application and returns it to the glycol stor-.

Many refrigerant options are available. TURBO can provide assistance in locating qualified companies familiar with the. A chiller piped in a sidestream position shown in Figure 8 can be loaded to any load condition by varying its chilled-water setpoint. Chiller Manual Installation Operation Maintenance INTRODUCTION Turbo Refrigerating is a supplier of fluid chillers icemaking and ice storage equipment. TURBO does not engineer or design fluid chilling systems ice systems ice plants or processing lines. 8 COOLING SSTEMS Cooling System Basics 10 Cooling System Basics In its simplest form an internal combustion engine is an energy conversion device. This stainless steel pump is specified to supply your process load with chilled glycol. They typically work in conjunction with a cooling tower which helps reduce the overall temperature of the cooling system. When designing a chilled-wat er system one of the first issues that must be addressed is to determine which type of water chiller to use.

Effect of variable primary chiller water flow system refrigerant pressure and leaving chilled water temperature for regular monitoring. Systems that employ water chillers are commonly called chilled-water systems. The chiller system is controlled so the system will not operate unless the circulation pump is running. TURBO can provide assistance in locating qualified companies familiar with the. 8 COOLING SSTEMS Cooling System Basics 10 Cooling System Basics In its simplest form an internal combustion engine is an energy conversion device. The layout of this system is the same as that shown in Fig. When selecting a chiller the application cooling temperature requirements and refrigerants cooling characteristics need to match.

Post a Comment for "Chiller System Pdf"